Have you ever looked at the washing instructions labels in your clothes and thought, “I don’t even know what that symbol means”? If you’re anything like me, everything goes in the washing machine on the one standard setting anyway! I know the odd few items which must go to the dry cleaners. Although even some of my older ‘dry clean only’ pieces also now go in the washing machine, on that one standard setting.

Who knew that there are so many different symbols for tumble drying or even an instruction for ‘line dry in the shade’? When it comes to the tumble dryer, I know the one or two items which can’t go in. But, similarly to the washing, everything else just gets thrown in the one setting. In terms of hanging washing on the line, it just gets hung on the line – sometimes that’s in the shade, sometimes it’s in the sun! My clothes still dry.

All of this got me thinking as to how we carry out process mapping. We purposely only map with boxes and arrows. Simple. No ambiguity. No needing a symbol decoder. ‘Just’ boxes and arrows.

It’s the simplicity of those ‘just’ boxes and arrows which give a process map its power. The beauty of that simplicity is that anyone in the organisation can look at the process map and understand it. There is no ambiguity around shapes. The directives of the process step are in the language used. Every step of the process map contains a verb and noun description of the activity taking place e.g. ‘update database’, ‘upload payment file’, ‘deliver order’. As well as the language used, we attach a resource to each box. This highlights who, or what (software, application, machine etc) is responsible for, and used, to make that process step happen. Again, simple. Every navigator of the map can instantly see who needs to fulfil that step. The boxes that are created for each step of the process can capture much more information if required. We work with our clients to understand their exact deliverables for every step of the process and can include links, attachments, images and even videos to assist in that being successfully carried out.

So, simplicity really is the key here. The way we process map leaves no room for uncertainty and no risk of employees feeling anxious about not understanding, or worse worried about getting something wrong. Our process maps are clear and defined. Those boxes and arrows guide the way for anyone to appreciate who needs to do what and when. Risk is mitigated, training can be delivered, process improvements can occur – all thanks to those boxes and arrows!

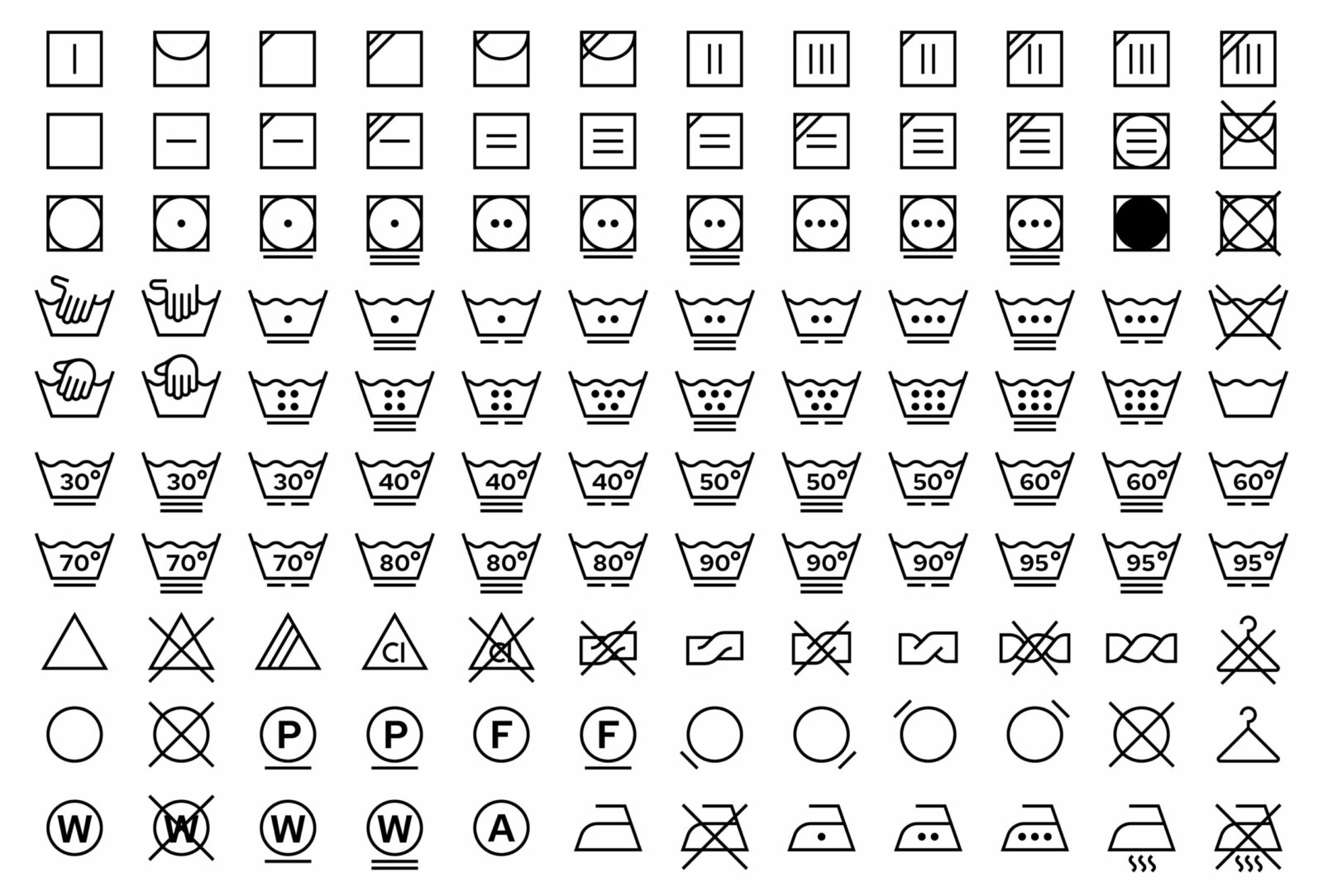

I’ll leave you with this image. Take a look and see how many of the symbols you definitively know. You may well be able to hazard a guess as to what some of them mean, but do you want your employees to be hazarding a guess when they’re running your business?